Mechanical fasteners are critical load-bearing components that decide the strength, safety, and service life of mechanical and structural systems. Whether it is pre-engineered buildings (PEB), heavy machinery, automotive assemblies, or industrial equipment, every joint ultimately depends on fasteners.

What Are Mechanical Fasteners?

Mechanical fasteners are devices used to join two or more components together, either temporarily or permanently, without altering the base material. As a result, they allow easy installation, inspection, maintenance, and replacement.

Moreover, fasteners:

- Transfer tensile and shear loads

- Maintain precise alignment

- Resist vibration and fatigue

- Ensure structural safety

Temporary vs Permanent Fasteners

Before selecting a fastener, it is essential to determine whether the joint will require future disassembly.

| Category | Removable | Examples |

| Temporary Fasteners | Yes | Bolts, Nuts, Screws, Pins |

| Permanent Fasteners | No | Rivets, Welded Studs, Clinch Fasteners |

While temporary fasteners are commonly used in machinery and PEB structures, permanent fasteners are preferred in applications such as aircraft, sheet-metal enclosures, and bridges.

BOLT – TYPES, SIZES & APPLICATIONS

Bolts are externally threaded fasteners designed to work with nuts or tapped holes. They primarily handle tensile loads, although they also resist shear when correctly installed.

Bolt Size, Head Size & Spanner Size Relationship (Critical Knowledge)

In metric hex bolts, the bolt diameter directly decides the head size and spanner size.

| Bolt Size | Thread Pitch (mm) | Hex Head / Spanner Size (mm) |

| M6 | 1.0 | 10 |

| M8 | 1.25 | 13 |

| M10 | 1.5 | 17 |

| M12 | 1.75 | 19 |

| M16 | 2.0 | 24 |

| M20 | 2.5 | 30 |

| M24 | 3.0 | 36 |

If the spanner size does not match this pattern, the bolt is likely imperial (British) or non-standard.

Bolt Grades & Head Markings

Markings on the head indicate bolt strength.

Example: Bolt Grade 10.9

- 10 × 100 = 1000 MPa (Ultimate Tensile Strength)

- 0.9 × 1000 = 900 MPa (Yield Strength) (0.9 represents 90% of the ultimate tensile strength)

Always match nut grade with bolt grade to prevent joint failure.

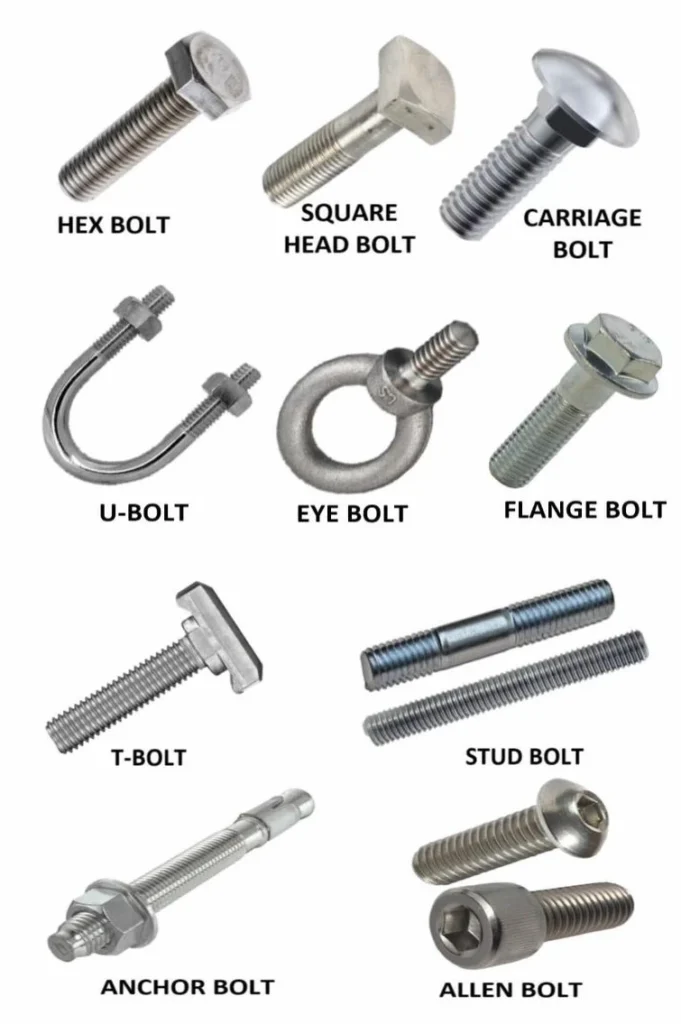

types of bolt

- hex Bolt

- The most commonly used bolt is due to its strength and ease of tightening.

- used in PEB structures, steel fabrication, machinery frames, automotive chassis.

- Square Head Bolt

- Provides better grip and resists rotation.

- used in Railways, heavy equipment, legacy machinery.

- Carriage Bolt

- A round head with a square neck prevents rotation in wood.

- used in Furniture, wooden platforms, conveyor supports.

- Eye Bolt

- Designed for lifting and tensile loading only. Side loading can reduce strength by up to 70%.

- used in Motor lifting, cable suspension, safety anchoring.

- u-bolt

- Used to clamp round components.

- used in Pipe supports, cable trays, vehicle suspension.

- T-Bolt

- Fits into T-slots for adjustable positioning.

- used in CNC machines, milling tables.

- Flange Bolt

- Integrated washer distributes load.

- used in Automotive engines, sheet-metal joints

- Anchor Bolt

- Transfers load from structure to concrete foundation, such as L-bolt, J-bolt, and straight bolt

- used in PEB columns, machinery foundations

- Stud Bolt

- Threaded on both ends, used with two nuts.

- used in Flanges, pressure vessels, boilers

- Allen Bolt (Socket Head Cap Screw)

- High-strength bolt for compact spaces, usually grade 12.9.

- used in Precision machinery, automotive engines, robotics

NUTS – TYPE & THREADS METHODS

Nuts clamp components together and are often the weakest link if incorrectly selected.

Metric vs British Threads (Fitment Rule)

| thread system | Measurement in | Common use |

| Metric (ISO) | mm | Global industrial |

| BSW / BSF | Inch | Old machinery |

| BSP | Pipe thread | Plumbing |

Type of Nuts

- Hex Nut – General purpose

- Square Nut – Heavy load

- Lock Nut (Nyloc) – Vibration resistance

- Castle Nut – Safety locking with cotter pin

- Wing Nut – Hand tightening

- Flange Nut – Load distribution

- Cap Nut – Thread protection

- Jam Nut – Locking

- T-Nut – Machine tables

- Slotted Nut – Safety locking

SCREWS – SELF-THREADING FASTENERS

Screws form or engage threads directly and do not require nuts.

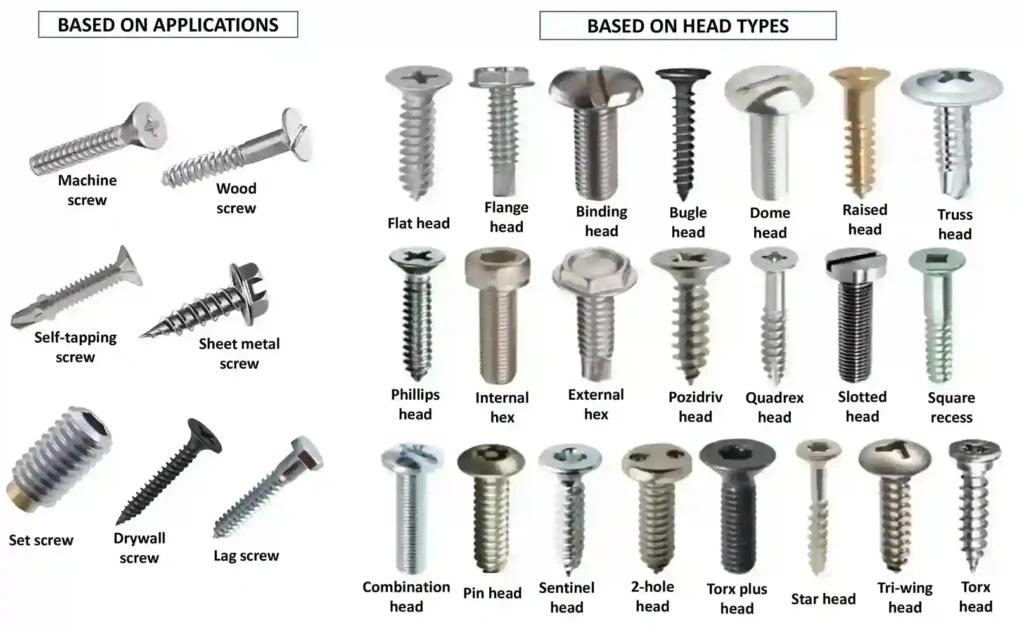

Types of screws

1.Based on Thread Formation Method

- Machine Screws : Require pre-tapped holes ,Uniform thread along shank, High dimensional accuracy. used in Electrical panels, machines, instruments, assemblies with frequent removal

- Self-Tapping Screws : Cut threads into softer materials, Sharp thread profile. used in Sheet metal, thin steel sections, plastic housings

- Thread-Forming Screws : Form threads without cutting, Stronger joint than self-tapping. used in Plastics, aluminum, soft alloys

2.Based on Material Being Fastened

- Wood Screws : Coarse, deep threads, Tapered shank. Used in Furniture, wooden structures, plywood fixing

- Sheet Metal Screws : Sharp point .Fine to coarse threads , used in HVAC ducts, enclosures, electrical boxes

- Drywall Screws : Bugle head, Hardened steel. used in Gypsum boards to steel/wood frames

3.Set Screws (Grub Screws) :

Used without a head to lock components on shafts. Used in Pulleys, gears, couplings, collars

4.based on head shape

Screw heads vary widely, from countersunk for flush finishes, to raised (Pan, Round, Truss, Button, Oval) for surface fastening, to hex for high torque, and specialized drives like Phillips, Pozidriv, Torx (Star), or Square for other tools.

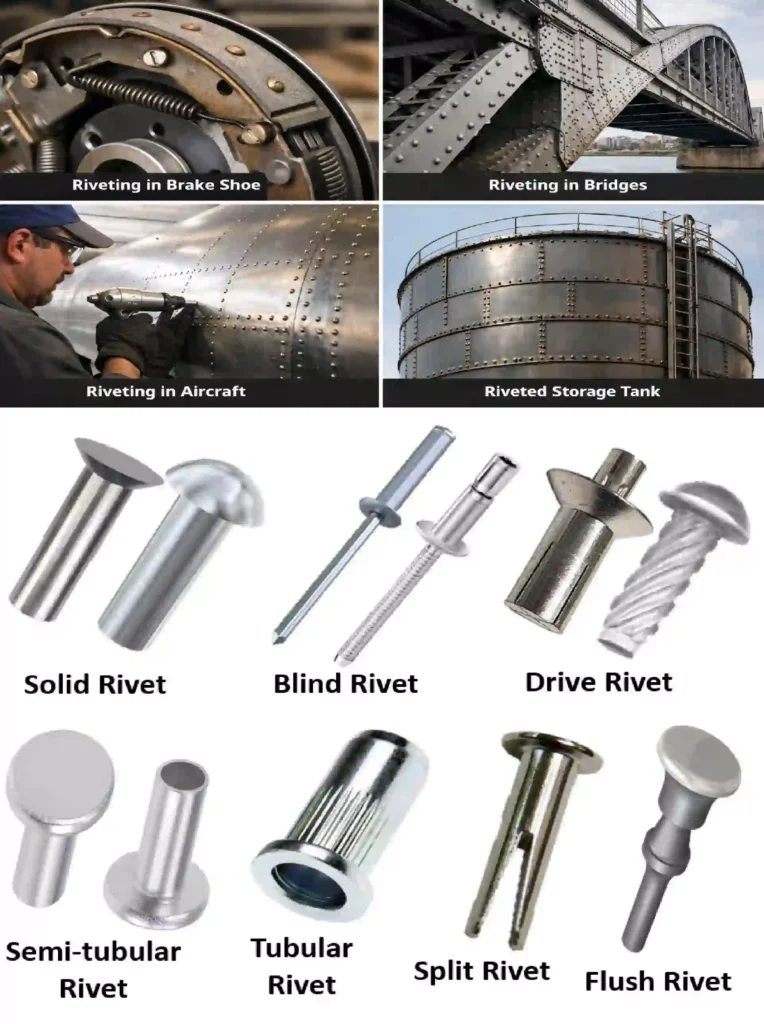

RIVETS – PERMANENT FASTENERS

Rivets are permanent mechanical fasteners that join materials by plastic deformation.

types of Rivets

1.Based on Installation Method

- Solid Rivets: Oldest and strongest type, require access from both sides. Used in Bridges, boilers, and aircraft structures

- Blind Rivets (Pop Rivets): Installed from one side, expand on the blind side. used in Sheet metal, enclosures, and repair works

2. Based on Construction

- Flush Rivet: Countersunk, used in Aircraft skins

- Tubular Rivet: Hollow shank, used for light-duty

- Semi-Tubular: Partial hollow, used in Hinges

- Drive Rivet: Hammer-driven, used in Nameplates

Rivets are chosen when disassembly is not required.

Key Characteristics of Rivets

- Permanent joint: Once installed, rivets cannot be removed without damage.

- Strong in shear: Rivets mainly resist sideways (shear) forces.

- Vibration resistant: They do not loosen under vibration.

- Cold installation: Fixed without heating, so no part distortion.

- Correct size matters: Proper rivet length and hole size ensure strength.

- Material compatibility: Similar materials prevent corrosion.

- Common applications: Aircraft, bridges, sheet metal, brake linings.

PINS – POSITIONING & LOCKING

Pins are locating, aligning, or locking elements, not load-clamping fasteners.

Types of Pins

- Dowel Pins: Precision ground, High shear capacity. used in Gearboxes, jigs, fixtures, and the alignment of machine parts

- Spring Pins (Roll Pins): Hollow, spring-loaded, absorb vibration. Used in Automotive assemblies, machinery

- Taper Pins: Tapered fit, Self-locking. used in Permanent positioning

- Cotter Pins: Split pin, prevents nut loosening, used in Castle nuts, shafts

- Clevis Pins: Used with a cotter pin, Shear loading. Used in Linkages, levers, and mechanical joints

- Lynch Pins: Quick-release pin used in Agricultural machinery

WASHERS – LOAD DISTRIBUTION & LOCKING

Washers are load-distributing and locking elements used with bolts and nuts. it prevent surface damage and loosening.

types of Washers

- Flat / Plain Washers: Spread load, Protect surface. Rule: OD ≈ 2 – 2.5 × bolt diameter

- Spring Washers: Provide axial force, resist loosening. Not suitable for high-vibration critical joints

- Lock Washers

- Tooth Washer – Electrical grounding

- Serrated Washer – Anti-slip

- Tab Washer – Mechanical locking

- Belleville Washer (Disc Spring): Acts as a spring, maintains preload. Used in High-temperature, vibration-prone joints

- Fender Washer: Large OD, Thin material. Used in Sheet metal, soft materials

SPECIAL & INDUSTRIAL FASTENERS

These fasteners are used where standard bolts or screws fail.

1. Structural & Foundation Fasteners

- Anchor Bolts: Transfer load to concrete, Types: L-bolt, J-bolt, straight bolt. Applications: PEB columns, machinery foundations

- Expansion Bolts: Mechanical expansion in concrete. Applications: Retrofit installations

- Chemical Anchors: Resin-based bonding, High load capacity. Applications: Heavy machinery, seismic zones

2. Adjustment & Tensioning Fasteners

- Turnbuckles: Adjust cable tension. Applications: Bracing systems, guy wires

- Threaded Rods: Continuous threading. Applications: Hangers, pipe supports, HVAC

3. Retaining Fasteners

- Circlips (Snap Rings): Retain components axially. Types: Internal, External. Applications: Bearings, shafts, gearboxes

4. Sheet Metal Special Fasteners

- Clinch nuts, Cage nuts, PEM fasteners, Speed clips

used in Electrical panels, enclosures, racks

Materials, Coatings & Corrosion Protection

Materials:

- Mild steel, carbon steel, alloy steel, SS304, SS316, brass, aluminum

Coatings:

- Black oxide, zinc plated, hot-dip Galvanized (HDG), dacromet, phosphate

HDG bolts require larger clearance holes.

Fastener Installation Rules – Quick Guide

Correct fastener installation is as important as bolt selection. Even a strong bolt can fail if installed incorrectly.

- Tightening Torque

- Torque creates clamping force between parts.

- Over-tightening stretches or breaks bolts.

- Under-tightening causes loosening.

- Lubricated threads need less torque.

- Use a torque wrench for important joints.

- Clearance Hole

- Bolt must pass freely through the hole.

- Tight holes cause bolt bending and stress.

- Oversized holes reduce joint grip.

- Galvanized bolts need slightly larger holes.

- Tapping Hole (Without Nut)

- Used when bolt screws directly into metal.

- Wrong tapping size damages threads.

- Rule: Tapping size = bolt diameter – thread pitch.

- Washer Usage

- Washers distribute load and protect surfaces.

- Mandatory for slotted or soft materials.

- Washer OD should be 2 – 2.5 × bolt diameter.

- Avoid spring washers in heavy structural joints.

- Thread Engagement

- Threads must fully engage.

- thread engagement in Steel: 1 × bolt diameter.

- Cast iron & Aluminium need more engagement.

- Poor engagement causes thread failure.

- Tightening Sequence

- Tighten bolts gradually, not fully at once.

- Use cross pattern for flanges and plates.

- Apply final torque in 2-3 steps.

- Bolt Projection

- Bolt should project 2-3 threads beyond nut.

- Too short – weak locking.

- Too long – corrosion risk.

- Nut & Bolt Matching

- Nut grade must match bolt grade.

- Never mix metric and inch threads.

- Threads should rotate freely by hand before tightening.

- Common Mistakes to Avoid

- Tightening by feel.

- Missing washers.

- Reusing stretched bolts.

- Using damaged or rusted fasteners.

Commonly Used Fastener Standards

- Indian Standards (IS / BIS) – Widely used in India, Middle East, Africa

- IS 1363 – Hex bolts & screws (product dimensions)

- IS 1367 – Technical delivery & mechanical properties

- IS 3757 – High strength structural bolts

- IS 800 – Structural steel usage (PEB relevance)

- International Standards (ISO)– Accepted globally ,Preferred in multinational projects

- ISO 898 – Mechanical properties of bolts & nuts

- ISO 4014 / 4017 – Hex bolt dimensions

- ISO 4032 – Hex nuts

- ISO 7091 / 7089 – Washers

- USA Standards (ASTM / ASME)-Mandatory in US projects, oil & gas, export jobs

- ASTM A325 / A490 – Structural bolts (PEB & bridges)

- ASTM A193 / A194 – Stud bolts & nuts (pressure vessels)

- ASME B18.2.1 – Bolt & screw dimensions

- ASME B18.2.2 – Nuts

- European Standards (EN)-Used in Europe & EPC projects

- EN 14399 – High-strength structural bolting

- EN ISO 4014 / 4017 – Metric bolts

Common Fastener Failures

- Wrong bolt grade

- Metric-imperial mismatch

- Over-tightening

- Missing washers

- Poor anchor installation

Final Note

- Bolts and nuts create clamping force,

- screws create fastening,

- rivets create permanence,

- pins create positioning,

- washers create reliability,

Fasteners are engineered systems, not simple hardware. Therefore, only when size, grade, head dimension, torque, material, coating, and installation work together do a joint become safe, durable, and reliable.