A Pre-Engineered Building (PEB) is a steel structure in which all components are designed, fabricated, and pre-engineered in a factory and then assembled at the site using bolted connections.

As a result, construction becomes faster, economical, and highly accurate.

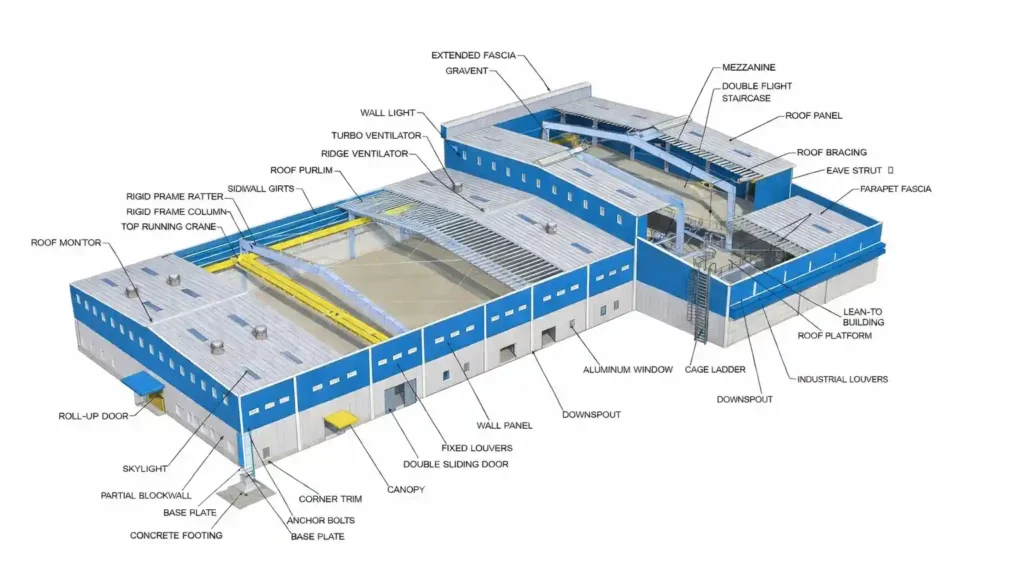

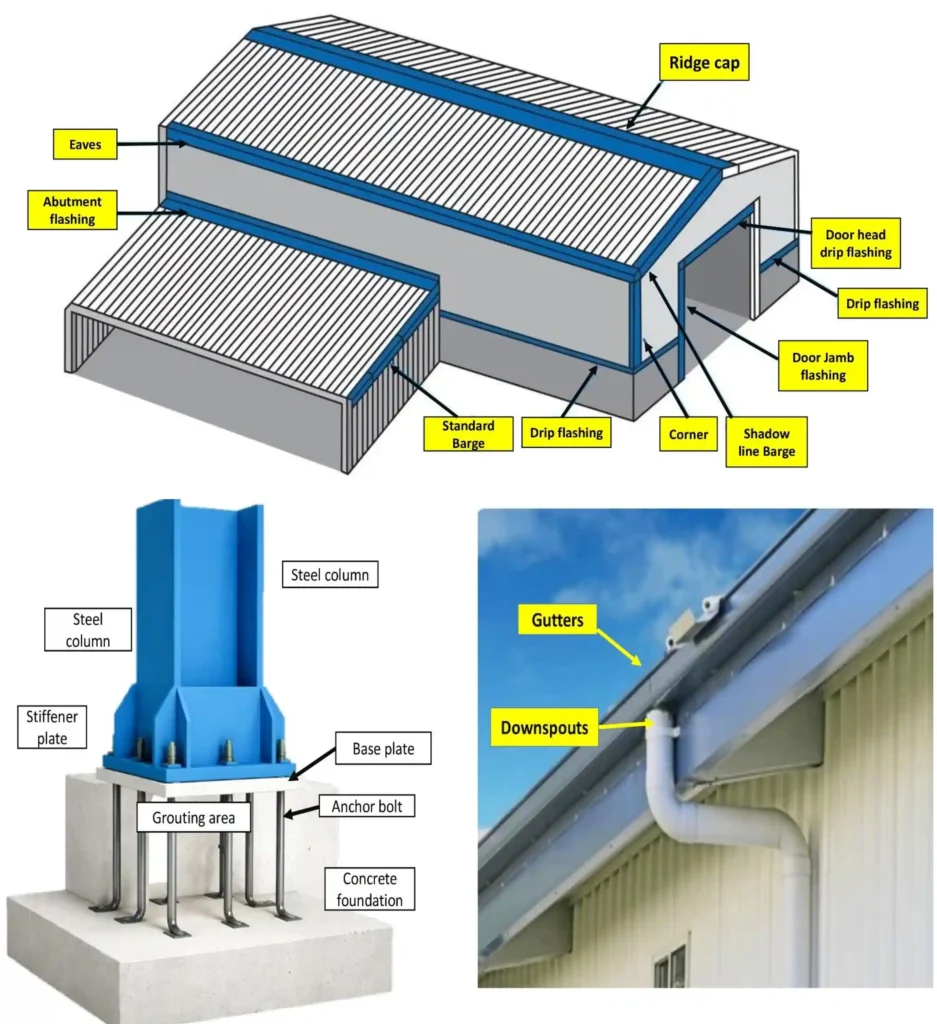

Pre-Engineered Building (PEB) Components

Understanding PEB components is essential before learning its benefits and uses. Therefore, below is a step-by-step classification of all Pre-Engineered Building components.

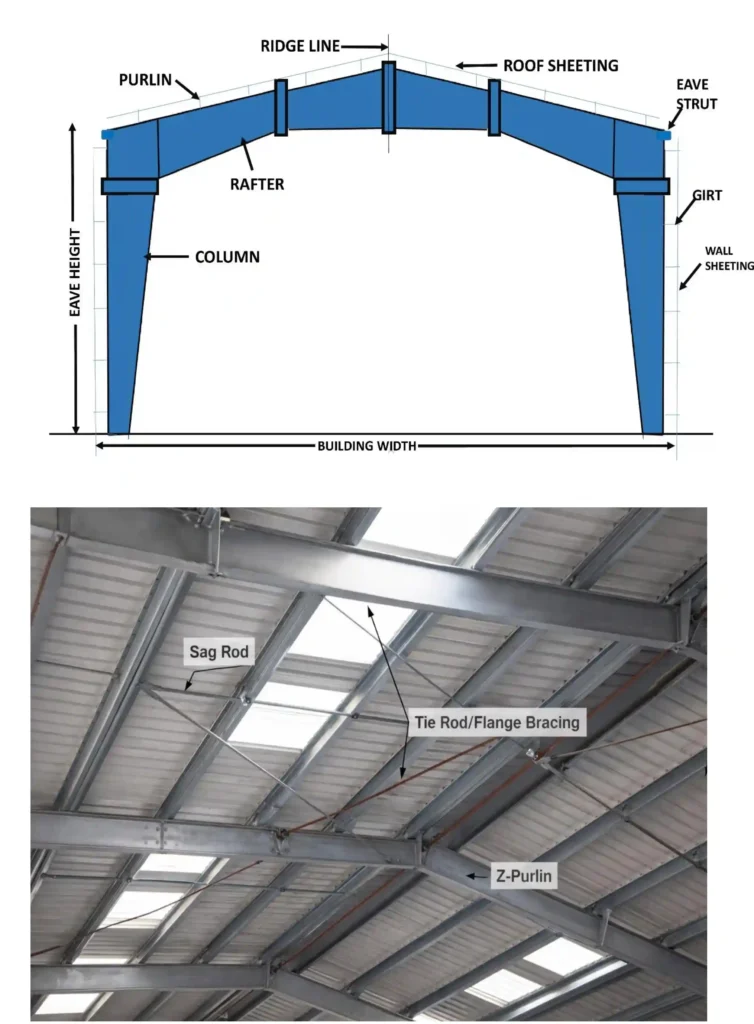

1. Primary Structural Components

Columns

- Vertical load-carrying members

- Transfer dead, live, wind, and seismic loads to the foundation

Rafters

- Horizontal or sloped members

- Support roof loads and connect columns

2. Secondary Structural Components

Purlins

- Support roof sheeting

Girts

- Support wall cladding

Eave Struts

- Connect the roof and wall at the eave level

Sag Rods

- Prevent buckling of purlins and girts

Tie Rods / Flange Bracing

Maintain spacing and alignment

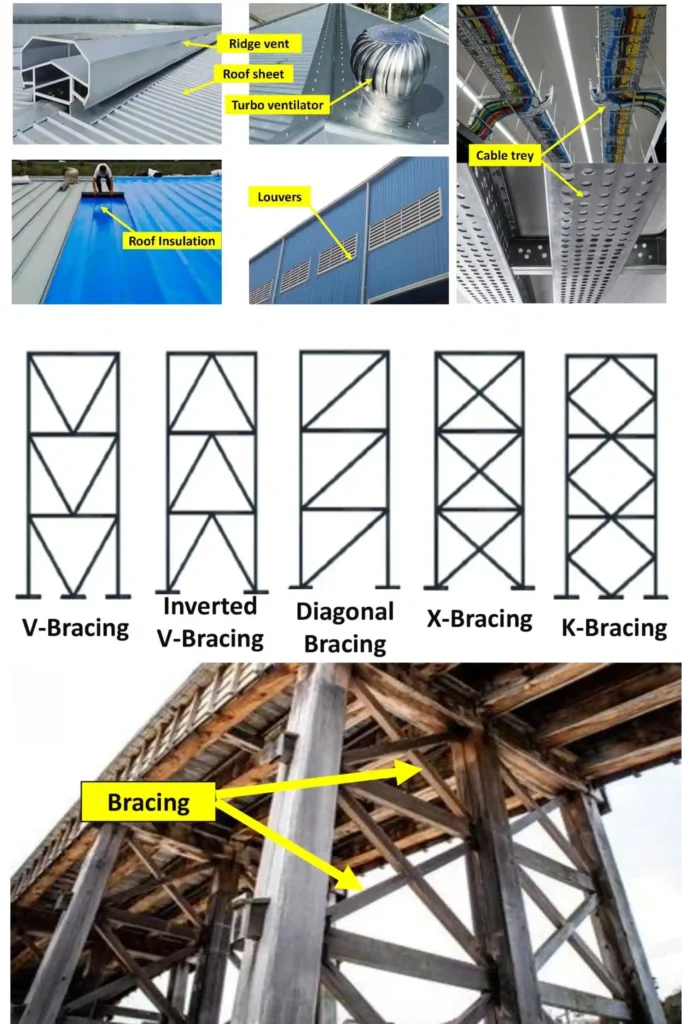

3. Bracing System

Rod Bracing

- Resists lateral loads

Cable Bracing

- Provides flexible stability for long spans

There are many other types of bracing, like channel bracing, angle bracing, etc

4. Roof System Components

Roof Sheets

- Weather protection

Ridge Cap

- Seals the roof ridge

Skylights / Roof Lights

- Natural daylight entry

Turbo Ventilators

- Heat and air exhaust

Gravity ventilator/GR Vent

- a passive ventilator that removes hot air naturally.

Roof Insulation

Thermal and sound control

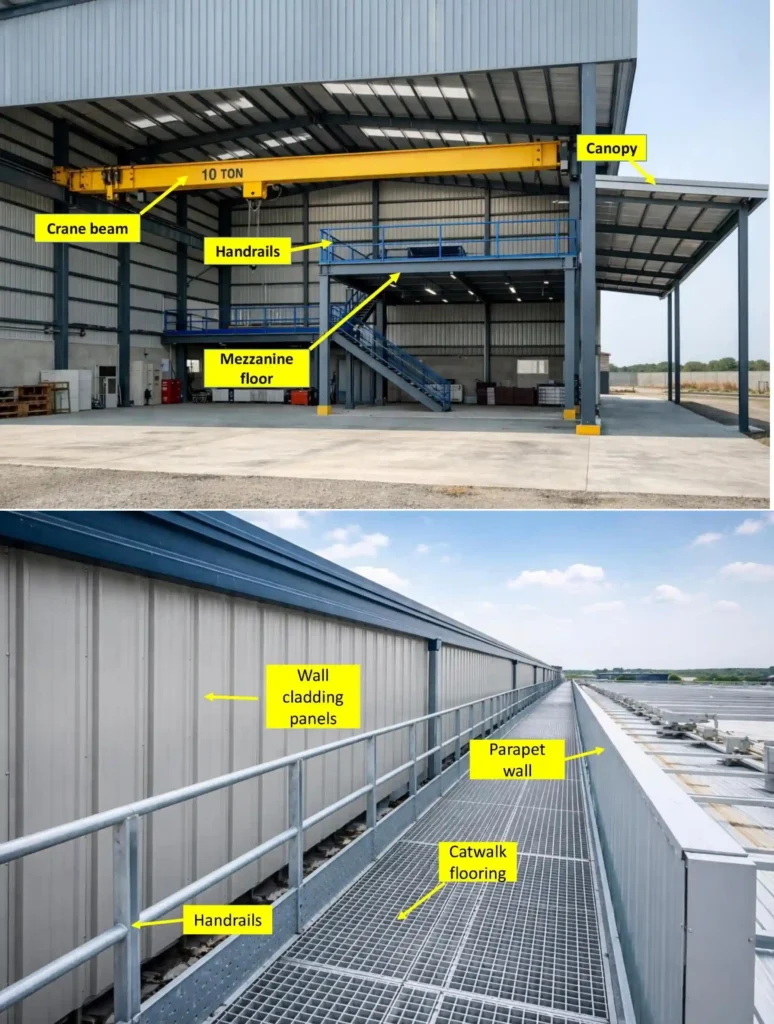

5. Wall System Components

Wall Cladding Panels

- External enclosure

Louvers

- Natural ventilation

Flashings (Corner, Eave, Trim)

- Prevent water leakage

Parapet Wall

- Architectural finish and safety

6. Openings and Access Systems

Doors

- Sliding doors, Rolling shutter doors, Personnel doors

Windows and Ventilators

- Light and airflow

7. Industrial & Add-On Components

Crane Beams

- Support overhead cranes

Mezzanine Floors

- Additional usable floor space

Canopies

Covered external working areas

8. Drainage System

Gutters

- Collect rainwater

Downspouts

- Safe water discharge

9. Fire Protection Components

- Fire-resistant paint or coating

- Sprinkler systems and fire exit provisions

10. Electrical & Utility Provisions

Cable Trays

- Electrical routing

Lighting and HVAC Supports

- Utility installations

11. Surface Protection System

Primer Coating

- Corrosion protection

Final Paint / Galvanizing

- Long-term durability

12. Foundation Components

Base Plates

- Column-foundation connection

Anchor Bolts

- Load transfer to the foundation

Grouting

- Uniform load distribution

13. Maintenance & Safety Accessories

Catwalks

- Roof access

Ladders

- Vertical maintenance access

Handrails and Safety Cages

Worker safety

Advantages of Pre-Engineered Buildings (PEB)

- Faster construction time

- Optimized steel usage

- Lower project cost

- Lightweight yet strong structure

- Reduced foundation requirement

- Factory-controlled quality

- Low maintenance

- Energy-efficient construction

- Easy future expansion

- Resistance to wind and seismic loads

- Environment-friendly material

- Large column-free spans

Applications of Pre-Engineered Buildings (PEB)

- Industrial sheds and factories

- Warehouses and logistics centers

- Cold storage facilities

- Commercial buildings and showrooms

- Aircraft hangars

- Sports halls and indoor stadiums

- Educational and institutional buildings

- Labor camps and prefab housing

- Metro depots and railway workshops

- Power plants and substations

- Parking sheds and garages

- Exhibition and convention halls

Read about Basic Mechanical Components and Their Functions